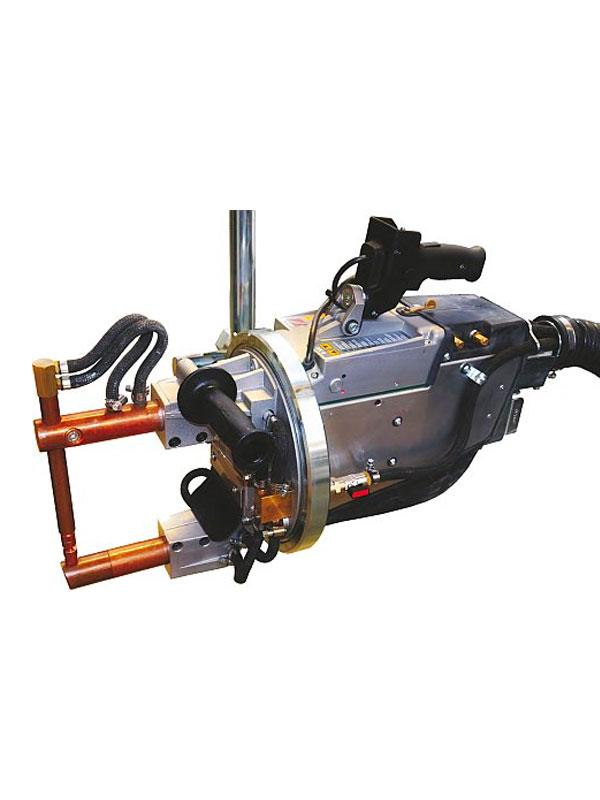

TECNA 3327 Suspended Spot Weld Gun

WSI-SELECT – In-Stock and For Sale at Weld Systems Integrators

TECNA 3327 Suspended Spot Weld Gun – WSI Serial #: B0220085

TECNA 3327 suspended spot weld gun [ WSI stock / serial #: B0220085 ] IN-STOCK and FOR SALE at Weld Systems Integrators. The TECNA 3327 is a 38 kVA, scissor-type, air-operated, medium-duty spot-welding gun with standard 9.8″ (250 mm) – 40.6″ (1030 mm) arms. NOTE: custom arm holder configurations are available.

WSI maintains an IN-STOCK inventory of new and used resistance welding equipment at our Warrensville Heights, Ohio location for quick shipment and delivery. Contact our knowledgeable sales team at 844-WSI-WELD or +1-216-475-5629 for immediate assistance.

EQUIPMENT QUOTEQuote RequestFeaturesSpecifications

Please submit the following form to request additional information.

Enter WSI Serial #: B0220085 on the following quote request form.

If you have any questions on WSI Select – IN-STOCK equipment available from Weld Systems Integrators, please call 844-WSI-WELD or +1-216-475-5629 and ask to speak with a WSI Engineer.

- Pneumatically-operated suspended gun with integrated TE300, TE470 or TE480 microprocessor-based welding controls.

- Intelligent Design, Small Dimensions, and High Welding Capacity deliver Maximum Productivity.

- High electrical efficiency.

- The totally-enclosed unit includes rubber bumpers in some areas, for safe and easy operation.

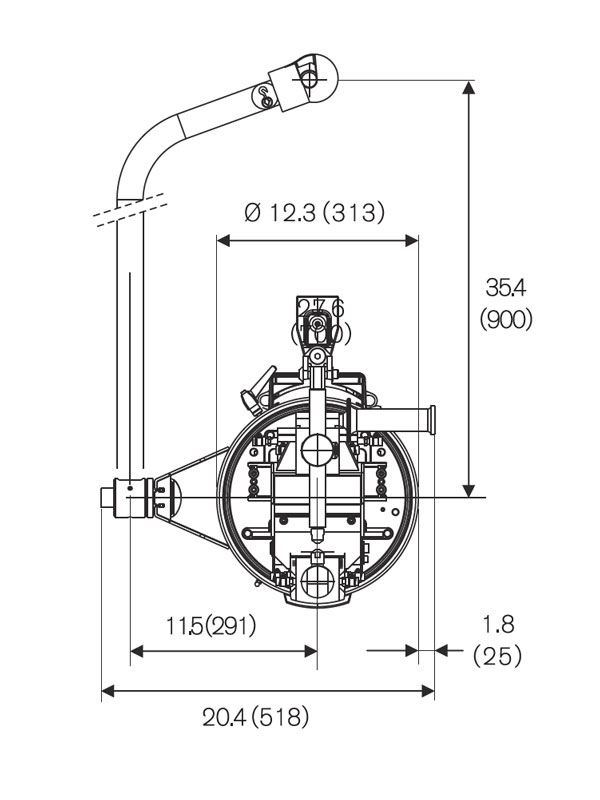

- Accurate maneuverability at any angle is guaranteed by gyro suspension mounted on sealed bearings, coupled with a TECNA balancer.

- Rotation lock allows the locking of multiple axes of motion.

- Accepts a broad range of standard and special arms to accommodate special applications. “C” type gun assists in accessing unconventional areas.

- Chromium copper electrode holders offer long life in a production environment and are designed for use at angles of up to 30°. Ask about WSI-exclusive 30-degree arms!

- Long, adjustable Welding Stroke enables welding in difficult-to-reach areas, including welding reinforcements and ribs.

- Temporary extra stroke (retraction stroke) allows for reaching into tough spots.

- Water-cooled transformer, with epoxy resin-coated windings for long life.

- Water-cooled arms, electrode holders, and electrodes for best performance and maximum use.

- SCR (Silicon-Controlled Rectifier) is insulated from the cooling circuit and includes a thermal cutoff switch for overheat protection.

- Lube-free chromium-plated cylinder and shaft offer a long service life in a production environment.

- Lube-free pneumatic circuit eliminates oil mist in your shop.

- Trigger Handle Safety prevents accidental initiation.

- Trigger Handle Controls enable selection between 2 or 4 welding programs, as well as Stage 1 ‘weld / no-weld’ function.

- New for 2017: Power Supply Cable is replaceable without opening up the welder!

| MODEL SPECIFICATIONS | UNITS | TECNA 3327 |

|---|---|---|

| WSI Serial Number | B0220085 | |

| Gun Type | Scissor (L) | |

| Power @ 50% Duty Cycle | kVA | 38 |

| Max Power | kVA | 110 |

| Short Circuit Current | A | 27,000 |

| Thermal Current @ 100% | kA | 5.4 |

| Secondary Voltage | V | 5 |

| * Supply Voltage (@60Hz) | V | 440 |

| Primary Cables Ø (up to 30m) | mm2 | 25 |

| Delayed Fuses @ 440VAC | A | 80 |

| Arm Spacing | in (mm) | 6.1 (155) |

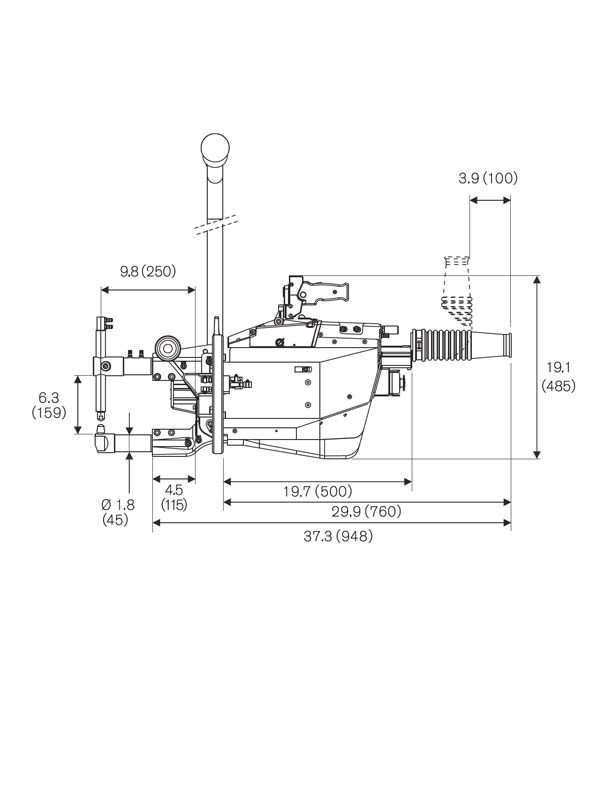

| Arm Minimum Length | in (mm) | 9.8 (250) |

| Max Electrode Force @ 116 psi (8 bar) | lbs. (daN) | 1529 (695) |

| Working Stroke | in (mm) | 0.4-1.0 (10-26) |

| Maximum Stroke | in (mm) | 1.8-2.4 (45-60) |

| Arm Maximum Length | in (mm) | 40.6 (1030) |

| Max Electrode Force @ 116 psi (8 bar) | lbs. (daN) | 343 (156) |

| Working Stroke | in (mm) | 1.6-3.9 (40-100) |

| Maximum Stroke | in (mm) | 6.5-8.9 (165-225) |

| Compressed Air Supply | psi (bar) | 94 (6.5) |

| Air per 1000 Spots @ 72.5 psi (500kP / 5 bar) | SCF (Nm3) | 265 (7.5) |

| Hose Inside Ø | in (mm) | 0.4 (10) |

| Water Cooling @ 36 psi (250 kP / 2.5 bar) | gpm (lpm) | 2.11 (8) |

| Max Thickness Mild Sheet Steel | ||

| w/90° Arms @ Min. Length | in (mm) | 0.20 x 0.20 (5 x 5) |

| w/90° Arms @ 20″ (508mm) | in (mm) | 0.14 x 0.14 (3.5 x 3.5) |

| w/90° Arms @ Max. Length | in (mm) | 0.08 x 0.08 (2 x 2) |

| w/90° Arms, Cross Wire Max Ø | in (mm) | 0.63 x 0.63 (16 x 16) |

| Welding Rate per Minute | ||

| 0.040 x 0.040″ (1x1mm) Class A | 100 | |

| 0.060 x 0.060″ (1.5 x 1.5mm) Class A | 44 | |

| 0.080 x 0.080″ (2x2mm) Class A | 20 | |

| 0.098 x 0.098″ (2.5 x 2.5mm) Class A | 14 | |

| 0.118 x 0.118″ (3x3mm) Class B | 8 | |

| Net Weight (w/cables, hoses, suspension & shortest arms) | lbs (kg) | 167 (76) |

| Packing Box Dimensions | in (mm) | 29.9 x 41.3 x 19.7 (760 x 1050 x 500) |

| Spring Balancer | ||

| Short Arms Capacity Required | lbs (kg) | 165-198 (75-90) |

| Short Arms Balancer Required | Model # | 9370BR |

| Long Arms Capacity Required | lbs (kg) | 198-231 (90-105) |

| Long Arms Balancer Required | Model # | 9371BR |