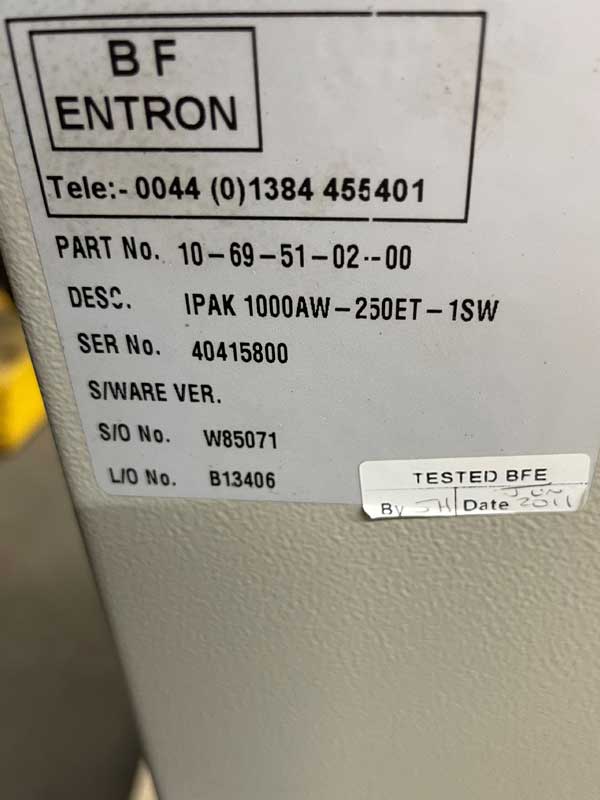

Used ENTRON IPAK – 10-69-51-02-00

WSI-SELECT – In-Stock and For Sale at Weld Systems Integrators

WSI Serial #: W-3132

Used ENTRON IPAK inverter weld control model #10-69-51-02-00 [ WSI stock / serial #: W-3132 ]. Ideal for MFDC applications. User friendly. Tested and warrantied for 6 months. This unit comes with WSPS Pendant and cable. Control cabinet with door-mounted timer, up to 64 programs, constant current control, and monitoring. Fitted into a sheet steel enclosure with circuit breaker, 24 VDC air valve power supply, appropriate line fusing, safety covers, and water-cooled MFDC Inverter Module.

WSI maintains an IN-STOCK inventory of new and used resistance welding equipment at our Warrensville Heights, Ohio location for quick shipment and delivery. Contact our knowledgeable sales team at 844-WSI-WELD or +1-216-475-5629 for immediate assistance.

EQUIPMENT QUOTEPlease submit the following form to request additional information.

Enter WSI Serial #: W-3132 on the following quote request form.

If you have any questions on WSI Select – IN-STOCK equipment available from Weld Systems Integrators, please call 844-WSI-WELD or +1-216-475-5629 and ask to speak with a WSI Engineer.

| SPECIFICATIONS | WSI Stock / Serial #: W-3132 |

|---|---|

| Manufacturer Name: | ENTRON |

| Type: | 1000 amp inverter |

| Mfg. Model #: | 10-69-51-02-00 |

| Voltage: | 480 |

| Phase: | 3 |

| Disconnect Size: | 250 amps |

| General Condition: | Used ENTRON IPAK inverter weld control model #10-69-51-02-00 [ WSI stock / serial #: W-3132 ]. Ideal for MFDC applications. User friendly. Tested and warrantied for 6 months. This unit comes with WSPS Pendant and cable. |

| Additional Details: | — |

| Warranty: | 6 months |

| Availability: | Immediate |

- Spot / Repeat / Roll-spot / Seam (dual heat) / Seam (preheat)

- Pulsation, Upslope and Downslope

- Dual weld intervals per program (Preheat and Weld)

- 64 programs (internal or external selection)

- Constant Current regulation

- Current/Power Monitoring: High/Low limits and Pre-limit

- Proportional valve controller (0–10 V or 4–20 mA)

- Pressure Monitoring: High/Low limits

- Programmable blocking on fault

- Weld Log keeps a history of recent welds

- Programmable outputs (events)

- Retract/High-lift control

- Single or dual gun operation

- Optional Constant Voltage regulation / Constant Power

- OHMA (Air over Oil) gun operation

- Up to 3 analog inputs (2 x 0–10 V, plus 1 x 0–10 V or 4–20 mA)

- Machine Sequencer Logic

- Chain – Weld programs may be linked together for multiple spot sequences

- Cascade configuration available – Up to 4 MFDC transformers

- High Current Output configurations available – up to 300 kA weld current capability, higher on special applications