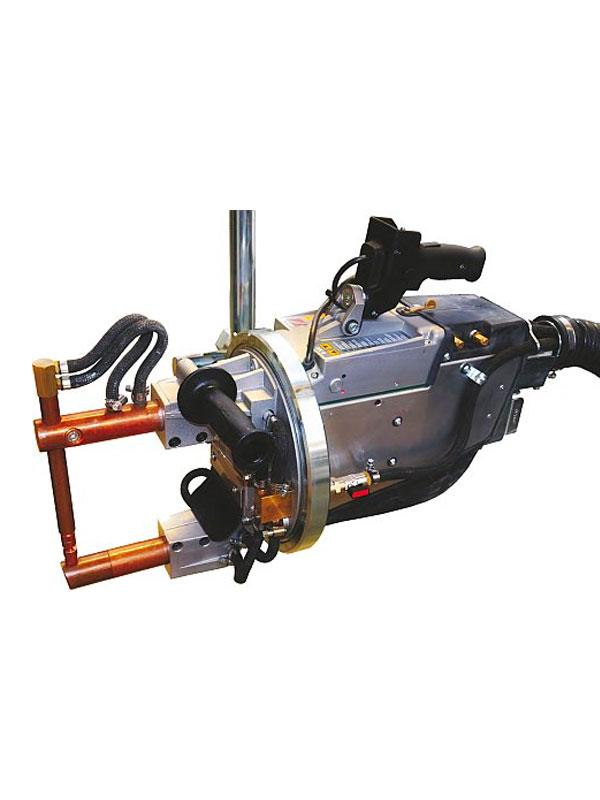

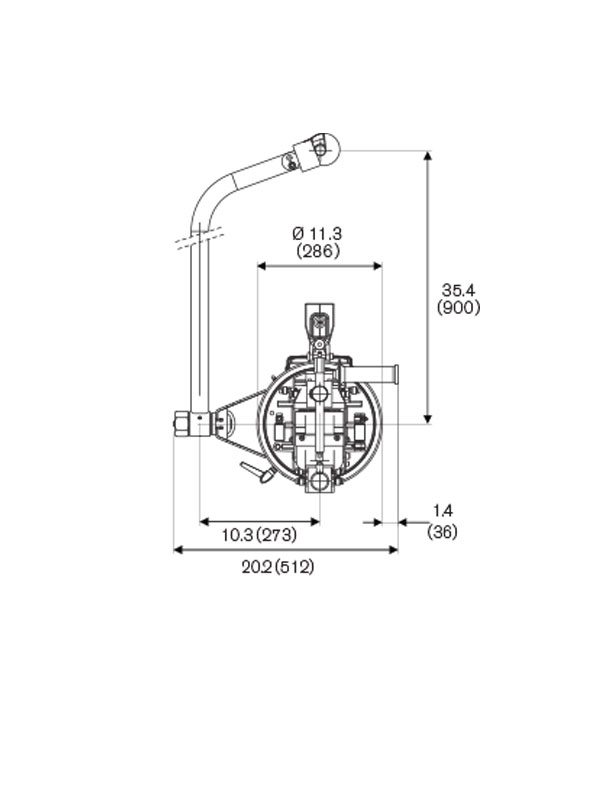

TECNA TE3321NX/LC Suspended AC Weld Gun

16 kVA | Air-Operated | Single-Phase AC

TECNA TE3321NX/LC Weld Gun

The TECNA TE3321NX/LC is a 16 kVA, single-phase AC, scissor-type spot weld gun IN-STOCK and FOR SALE at Weld Systems Integrators. The TE3321NX/LC is a versatile and powerful air-operated suspended spot welding gun available with customer-select arms from 7.48″ – 25.59″ and custom arm holder configurations. The NEW RCD (residual current device) version includes the TECNA ground integrity monitor to provide increased operator electrical safety.

- Model: TECNA TE3321NX

- Gun type: Scissor-type

- Power @ 50% duty cycle: 16 kVA

- Power supply: Single-phase AC

- Max. weld current: 16,000 amps

- Max. weld force: 213 lbs.

- INCLUDES: TECNA ground integrity monitor

- NX/LC model includes 49 ft. (15 m) main cables

Current IN-STOCK Inventory: 1

Weld Systems Integrators, a stocking master distributor of TECNA industrial resistance welders, maintains an inventory at our Warrensville Heights, Ohio, location. Please reach out to our knowledgeable sales team at 844-WSI-WELD or 216-475-5629 for current availability.

Please submit the following form to request additional information.

Enter “TECNA-TE3321NX/LC” on the following quote request form.

If you have any questions on WSI Select – IN-STOCK equipment available from Weld Systems Integrators, please call 844-WSI-WELD or 216-475-5629 and ask to speak with a WSI Engineer.

- High productivity achieved with rational design, reduced dimensions, and high welding capacity.

- High electric efficiency.

- Reduced installation costs.

- Totally enclosed, rubber protected for easy and safe operation.

- Gyro suspension on sealed bearings together with a spring balancer guarantees accurate maneuverability at any degree.

- Rotation locking device.

- Large selection of arms, enabling welder set-up according to the work exigencies.

- Chrome-copper electrode-holders for heavy-duty and long life, designed for both straight and angled assembling.

- Adjustable electrode distance, adjustable short working stroke for heavy-duty.

- Temporary extra stroke to reach the areas to be welded.

- Long working stroke to weld reinforcement ribs, jobs in areas that are difficult to reach.

- Water-cooled transformer, with epoxy resin-coated windings.

- Water-cooled arms, electrode-holders, and electrodes.

- Synchronous SCR contactor insulated from the cooling water circuit with a protection thermostat.

- Oilless chromium-plated cylinder and shaft for heavy-duty operation and long life.

- Safety device placed on the handle, preventing any accidental start.

- Supplied complete with an earth leakage switch with safety control.

- Quick replacement of the supply cable; it is not necessary to open up the welder to carry out this operation.

| SPECIFICATIONS | 3321NX | 3322NX | 3323NX | 3324 | 3327NX | 3328NX | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gun Type | Scissor-type | Scissor-type | C-type | Scissor-type | Scissor-type | Scissor-type | ||||||

| Power @ 50% Duty Cycle | 16 kVA | 23 kVA | 23 kVA | 23 kVA | 38 kVA | 38 kVA | ||||||

| Max Power | 37 kVA | 65 kVA | 63 kVA | 52 kVA | 110 kVA | 92 kVA | ||||||

| Short Circuit Current | 16000 A | 21000 A | 21000 A | 16500 A | 27000 A | 22500 A | ||||||

| Thermal Current @ 100% | 4 kA | 4.25 kA | 4.25 kA | 4.25 kA | 5.4 kA | 5.4 kA | ||||||

| Secondary Voltage | 2.8 V | 3.8 V | 3.8 V | 3.8 V | 5 V | 5 V | ||||||

| * Supply Voltage (@60Hz) | 220 or 440 V | 220 or 440 V | 220 or 440 V | 220 or 440 V | 440 V | 440 V | ||||||

| Primary Cables Ø (up to 30m) | 10 mm2 | 16 mm2 | 16 mm2 | 16 mm2 | 25 mm2 | 25 mm2 | ||||||

| Delayed Fuses @ 440VAC | 32 A | 40 A | 40 A | 40 A | 80 A | 80 A | ||||||

| Arm Spacing | 6.5 in. (165 mm) | 6.5 in. (165 mm) | 4.7 in. (120 mm) | 8.9 in. (225 mm) | 6.1 in. (155 mm) | 11.0 in. (280 mm) | ||||||

| Arm Minimum Length | 7.5 in. (190 mm) | 7.5 in. (190 mm) | – | 9.8 in. (250 mm) | 9.8 in. (250 mm) | 9.8 in. (250 mm) | ||||||

| Max Electrode Force @ 116 psi (8 bar) | 629 lbs. (286 daN) | 744 lbs. (338 daN) | 660 lbs. (300 daN) | 590 lbs. (268 daN) | 1529 lbs. (695 daN) | 1529 lbs. (695 daN) | ||||||

| Working Stroke | 0.2-1.0 in. (6-25 mm) | 0.2-0.8 in. (5-20 mm) | 0.2-0.8 in. (5-20 mm) | 0.2-1.0 in. (6-25 mm) | 0.4-1.0 in. (10-26 mm) | 0.4-1.0 in. (10-26 mm) | ||||||

| Maximum Stroke | 1.2-1.9 in. (30-48 mm) | 1.1-1.6 in. (28-40 mm) | 1.4-2.0 in. (35-50 mm) | 1.2-1.9 in. (30-48 mm) | 1.8-2.4 in. (45-60 mm) | 1.8-2.4 in. (45-60 mm) | ||||||

| Arm Maximum Length | 25.6 in. (650 mm) | 31.5 in. (800 mm) | – | 25.6 in. (650 mm) | 40.6 in. (1030 mm) | 32.3 in. (820 mm) | ||||||

| Max Electrode Force @ 116 psi (8 bar) | 209 lbs. (95 daN) | 205 lbs. (93 daN) | – | 249 lbs. (113 daN) | 343 lbs. (156 daN) | 431 lbs. (196 daN) | ||||||

| Working Stroke | 0.7-2.8 in. (18-72 mm) | 0.7-2.8 in. (18-72 mm) | – | 0.6-2.4 in. (15-60 mm) | 1.6-3.9 in. (40-100 mm) | 1.2-3.0 in. (30-75 mm) | ||||||

| Maximum Stroke | 3.5-5.5 in. (90-140 mm) | 4.0-5.7 in. (102-146 mm) | – | 3.3-4.7 in. (84-120 mm) | 6.5-8.9 in. (165-225 mm) | 5.1-6.9 in. (130-175 mm) | ||||||

| Compressed Air Supply | 94 psi (6.5 bar) | 94 psi (6.5 bar) | 94 psi (6.5 bar) | 94 psi (6.5 bar) | 94 psi (6.5 bar) | 94 psi (6.5 bar) | ||||||

| Air per 1000 Spots @ 72.5 psi (500kP / 5 bar) | 141 SCF (4 Nm3) | 141 SCF (4 Nm3) | 141 SCF (4 Nm3) | 141 SCF (4 Nm3) | 265 SCF (7.5 Nm3) | 265 SCF (7.5 Nm3) | ||||||

| Hose Inside Ø | 0.4 in. (10 mm) | 0.4 in. (10 mm) | 0.4 in. (10 mm) | 0.4 in. (10 mm) | 0.4 in. (10 mm) | 0.4 in. (10 mm) | ||||||

| Water Cooling @ 36 psi (250 kP / 2.5 bar) | 1.85 gpm (7 lpm) | 1.85 gpm (7 lpm) | 1.85 gpm (7 lpm) | 1.85 gpm (7 lpm) | 2.11 gpm (8 lpm) | 2.11 gpm (8 lpm) | ||||||

| Max Thickness Mild Sheet Steel | ||||||||||||

| w/90° Arms @ Min. Length | 0.12 x 0.12 in. (3 x 3 mm) | 0.16 x 0.16 in. (4 x 4 mm) | 0.16 x 0.16 in. (4 x 4 mm) | 0.14 x 0.14 in. (3.5 x 3.5 mm) | 0.20 x 0.20 in. (5 x 5 mm) | 0.20 x 0.20 in. (5 x 5 mm) | ||||||

| w/90° Arms @ 20" (508mm) | 0.07 x 0.07 in. (1.8 x 1.8 mm) | 0.12 x 0.12 in. (3 x 3 mm) | – | 0.12 x 0.12 in. (3 x 3 mm) | 0.14 x 0.14 in. (3.5 x 3.5 mm) | 0.14 x 0.14 in. (3.5 x 3.5 mm) | ||||||

| w/90° Arms @ Max. Length | 0.05 x 0.05 in. (1.2 x 1.2 mm) | 0.08 x 0.08 in. (2 x 2 mm) | – | 0.08 x 0.08 in. (2 x 2 mm) | 0.08 x 0.08 in. (2 x 2 mm) | 0.10 x 0.10 in. (2.5 x 2.5 mm) | ||||||

| w/90° Arms, Cross Wire Max Ø | 0.39 x 0.39 in. (10 x 10 mm) | 0.55 x 0.55 in. (14 x 14 mm) | 0.55 x 0.55 in. (14 x 14 mm) | 0.47 x 0.47 in. (12 x 12 mm) | 0.63 x 0.63 in. (16 x 16 mm) | 0.63 x 0.63 in. (16 x 16 mm) | ||||||

| Welding Rate per Minute | ||||||||||||

| 0.040 x 0.040" (1x1mm) Class A | 66 | 80 | 80 | 80 | 100 | 100 | ||||||

| 0.060 x 0.060" (1.5 x 1.5mm) Class A | - | 32 | 32 | 32 | 44 | 44 | ||||||

| 0.080 x 0.080" (2x2mm) Class A | 14 | 16 | 16 | 16 | 20 | 20 | ||||||

| 0.098 x 0.098" (2.5 x 2.5mm) Class A | - | - | - | - | 14 | 14 | ||||||

| 0.118 x 0.118" (3x3mm) Class B | - | - | - | - | 8 | 8 | ||||||

| Net Weight (w/cables, hoses, suspension & shortest arms) | 101 lbs. (46 kg) | 114 lbs. (52 kg) | 117 lbs. (53 kg) | 121 lbs. (55 kg) | 167 lbs. (76 kg) | 172 lbs. (78 kg) | ||||||

| Packing Box Dimensions | 12 x 33.5 x 21.7 in. (300 x 850 x 550 mm) | 12 x 33.5 x 21.7 in. (300 x 850 x 550 mm) | 13 x 44.1 x 24.8 in. (330 x 1120 x 630 mm) | 13 x 44.1 x 24.8 in. (330 x 1120 x 630 mm) | 29.9 x 41.3 x 19.7 in. (760 x 1050 x 500 mm) | 29.9 x 41.3 x 19.7 in. (760 x 1050 x 500 mm) | ||||||

| Spring Balancer | ||||||||||||

| Short Arms Capacity Required | 99-121 lbs. (45-55 kg) | 121-143 lbs. (55-65 kg) | 121-143 lbs. (55-65 kg) | 121-143 lbs. (55-65 kg) | 165-198 lbs. (75-90 kg) | 165-198 lbs. (75-90 kg) | ||||||

| Short Arms Balancer Required | Model: 9367BR | Model: 9368BR | Model: 9368BR | Model: 9368BR | Model: 9370BR | Model: 9370BR | ||||||

| Long Arms Capacity Required | 121-143 lbs. (55-65 kg) | 143-165 lbs. (65-75 kg) | – | 143-165 lbs. (65-75 kg) | 198-231 lbs. (90-105 kg) | 198-231 lbs. (90-105 kg) | ||||||

| Long Arms Balancer Required | Model: 9368BR | Model: 9369BR | – | Model: 9369BR | Model: 9371BR | Model: 9371BR | ||||||