Used ENTRON IPAK

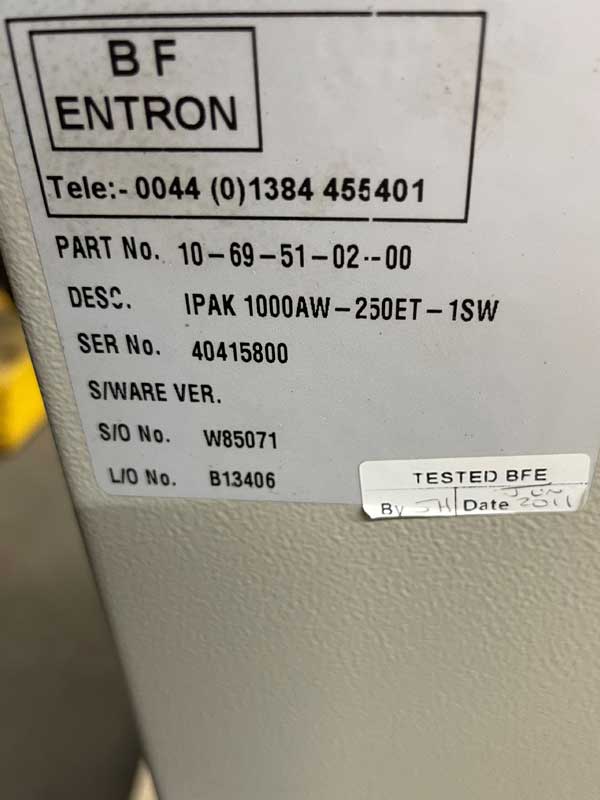

ENTRON Model No.: 10-69-51-02-00

MFDC / Inverter Weld Control

Used ENTRON IPAK MFDC / inverter weld control model #10-69-51-02-00 FOR SALE. Ideal for MFDC applications. User friendly. Tested and warrantied for 6 months. This unit comes with WSPS Pendant and cable. Control cabinet with door-mounted timer, up to 64 programs, constant current control, and monitoring. Fitted into a sheet steel enclosure with circuit breaker, 24 VDC air valve power supply, appropriate line fusing, safety covers, and water-cooled MFDC Inverter Module.

Current IN-STOCK Inventory: 1

WSI maintains an IN-STOCK inventory of new and used resistance welding equipment at our Warrensville Heights, Ohio location. Contact our knowledgeable sales team at 844-WSI-WELD or 216-475-5629 for immediate assistance.

EQUIPMENT QUOTEPlease submit the following form to request additional information.

Enter ENTRON IPAK on the following quote request form.

If you have any questions on WSI Select – IN-STOCK equipment available from Weld Systems Integrators, please call 844-WSI-WELD or 216-475-5629 and ask to speak with a WSI Engineer.

| SPECIFICATIONS | ENTRON IPAK |

|---|---|

| Manufacturer Name: | ENTRON |

| Type: | 1000 amp inverter |

| Mfg. Model #: | 10-69-51-02-00 |

| Voltage: | 480 |

| Phase: | 3 |

| Disconnect Size: | 250 amps |

| General Condition: | Used ENTRON IPAK inverter weld control model #10-69-51-02-00. Ideal for MFDC applications. User friendly. Tested and warrantied for 6 months. This unit comes with WSPS Pendant and cable. |

| Additional Details: | — |

| Warranty: | 6 months |

| Availability: | Immediate |

- Spot / Repeat / Roll-spot / Seam (dual heat) / Seam (preheat)

- Pulsation, Upslope and Downslope

- Dual weld intervals per program (Preheat and Weld)

- 64 programs (internal or external selection)

- Constant Current regulation

- Current/Power Monitoring: High/Low limits and Pre-limit

- Proportional valve controller (0–10 V or 4–20 mA)

- Pressure Monitoring: High/Low limits

- Programmable blocking on fault

- Weld Log keeps a history of recent welds

- Programmable outputs (events)

- Retract/High-lift control

- Single or dual gun operation

- Optional Constant Voltage regulation / Constant Power

- OHMA (Air over Oil) gun operation

- Up to 3 analog inputs (2 x 0–10 V, plus 1 x 0–10 V or 4–20 mA)

- Machine Sequencer Logic

- Chain – Weld programs may be linked together for multiple spot sequences

- Cascade configuration available – Up to 4 MFDC transformers

- High Current Output configurations available – up to 300 kA weld current capability, higher on special applications