TECNA 9520RL Food Industry Tool Balancers IN-STOCK

Zero-gravity balancer with NSF-H1 certified food-grade grease and stainless steel / rustproof exterior materials.

NEW TECNA 9520RL Tool Balancers

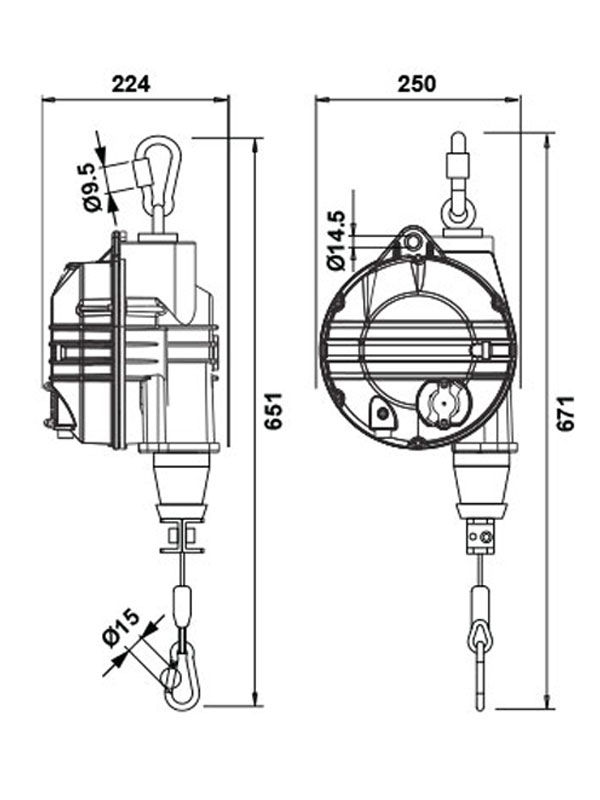

TECNA 9520RL zero-gravity food industry balancer is a NEW product line designed for food and beverage, meat processing, dairy, bakery and confectionery, and industrial washing and sanitizing applications. The 9520RL features a cast aluminum housing with special high-strength Rilsan® treatment, and stainless steel cable with a capacity of 26.46 – 44.09 lbs. (12.0 – 20.0 kg) and a stroke length of 106.3 in (2700 mm).

- Cast aluminum body [ Rilsan® treatment ]

- Zero-gravity rust-proof stainless steel

- Food-grade grease NSF-H1 certified

- Oxidation and chemical-resistant

TECNA 9520RL Balancers IN-STOCK: 1

EQUIPMENT QUOTE* LARGE ORDERS: For orders of 10 balancers or more, please contact Weld Systems Integrators at 844-WSI-WELD, 216-475-5629 or EMAIL, and we will assist with your requirements. Large orders may be subject to additional discounts.

| SPECIFICATION | UNITS | TECNA TE9520RL |

|---|---|---|

| Lower capacity | lbs. | 26.5 |

| kg | 12.0 | |

| Upper capacity | lbs. | 44.1 |

| kg | 20.0 | |

| Stroke length | in. | 106 |

| mm | 2700 | |

| Cable / rope type | Stainless steel | |

| Body material | Cast aluminum body [ Rilsan® treatment ] | |

| NSF-H1 Certified Grade Grease | Included | |

| BALANCER VERSION | ||

| Designated “LIL” and “IL” | Retractor balancer | |

| Designated “RL” | Zero-gravity balancer | |

| OPTIONAL VERSION | ||

| Stainless steel locking / unlocking device (version .B1) | Available | |

TECNA balancers make tools nearly weightless, reducing operator fatigue and improving safety and ergonomics. As the tool is repositioned the stainless steel cable extends and retracts smoothly from the aluminum housing, providing a full range of motion. Tension adjustment is easy and precise.

- Cast aluminum housing with special hard anodization, resistant to oxidation and chemical aggression

- Smoother surface facilitates cleaning and sanitization

- Food grade rope guide, shock absorber, and wire cap

- Rustproof and stainless steel exterior materials

- NSF-H1 certified food grade grease

- Ribbed and sealed monobloc construction in aluminum alloy

- Stainless steel rope

- Adjustable capacity by means of a worm screw

- Auxiliary safety suspension

- Safety device against load dropping due to the spring breakage | >3k

- Upper rotary suspension with safety hook

- Locking device to block the load at any height

- Adjustable stroke limiting device

- Taper drum rotating on ball bearings

- Cable guide in antifriction material

- Inert spring drum assembly

- Polyamides thimble

* Features and specifications may vary, and are subject to change without notice

TECNA offers both RETRACTOR and ZERO-GRAVITY food industry balancer models.

TECNA food industry retractor balancers are designated “LIL” and “IL” (example: TECNA 9336LIL and 9336IL Retractor Balancers).

TECNA food industry zero-gravity balancers are designated “RL” (example: TECNA 9354RL Zero-Gravity Balancers).

OPTIONAL ACCESSORY “B1” – Locking-unlocking device with improved control from the floor (chain and handle in stainless steel). Available for food industry zero-gravity balancer models 9502RL – 9509RL and 9520RL – 9525RL.

If you have questions or would like help selecting the right food industry retractor balancer for your application, please contact a customer service representative at 844-44-TECNA or 216-475-5629. or sales@balancersdirect.com.

Please submit the following form to request additional information.

Enter “TECNA 9520RL” on the following quote request form.

If you have any questions on WSI Select – IN-STOCK equipment available from Weld Systems Integrators, please call 844-WSI-WELD or 216-475-5629 and ask to speak with a WSI Engineer.